Concrete Batch Plants

Durable • Reliable • Innovative

Vince Hagan concrete batching plants are designed to meet the diverse and stringent demands of concrete production industries. Using innovative technologies to monitor plant components, designing plants for easy mobility and erection, and using the heaviest plate steel to manufacture our plants here in the USA, Vince Hagan produces batching plants that are the most durable, reliable, and dependable on the market. The Vince Hagan difference is reason we are the most trusted name among the largest concrete producers worldwide.

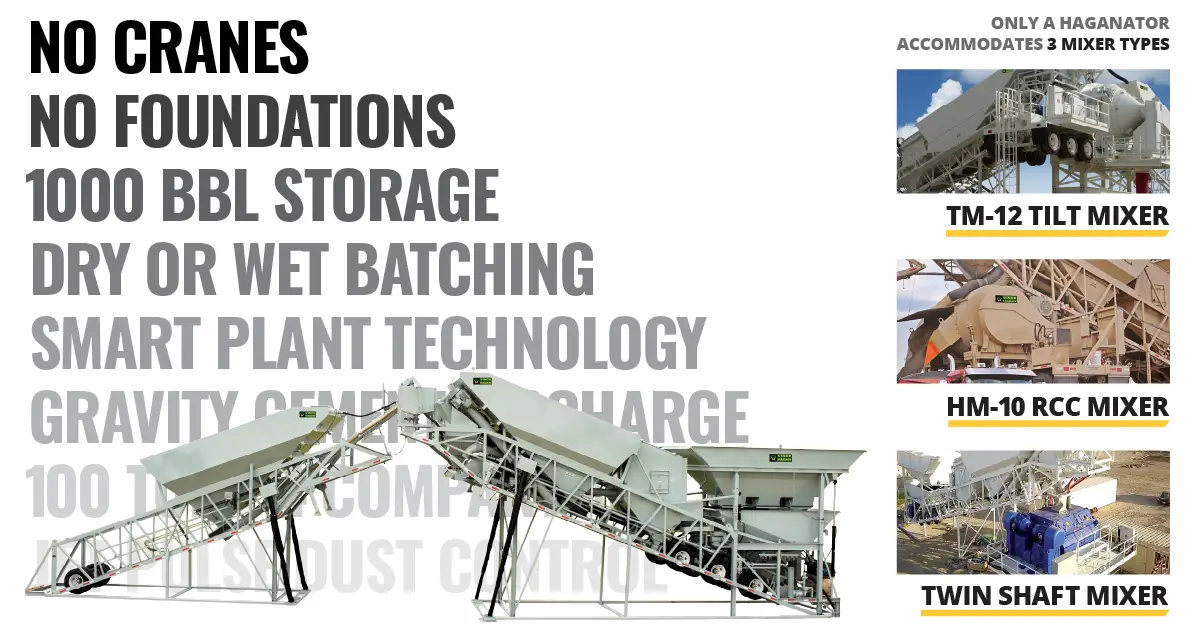

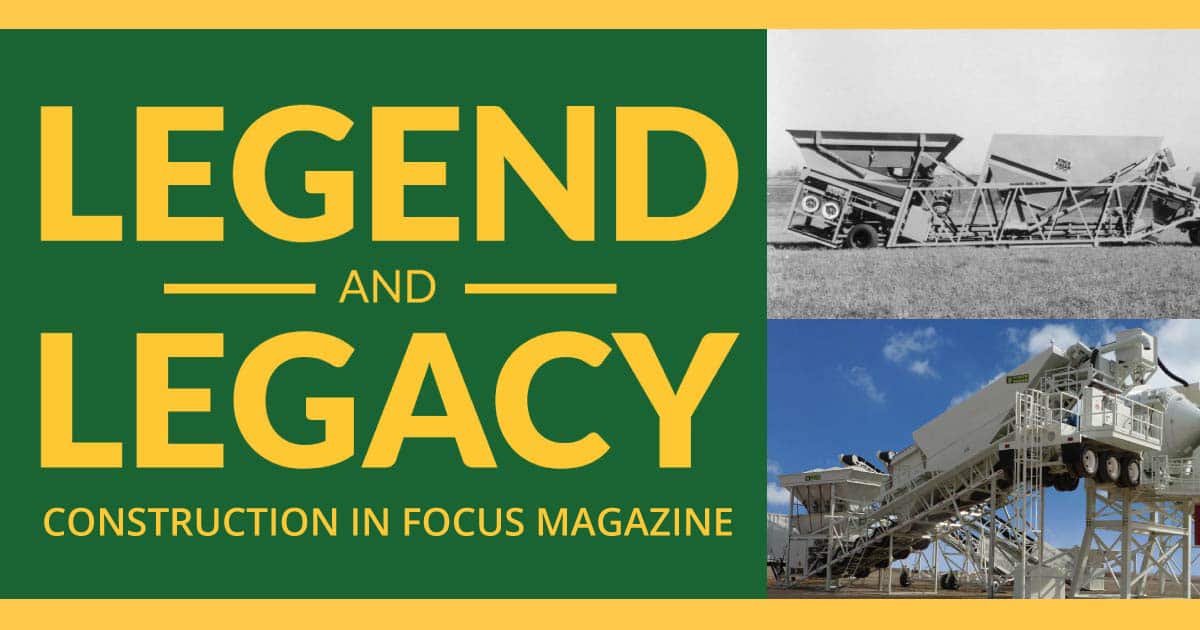

Buy a Mobile Batching Plant From the Company that Invented It

In 1956, Mr. Vince Hagan, founder of The Vince Hagan Company, started with an original idea: he would design, build, and patent (U.S. patent #3,251,484) the very first fully mobile concrete batch plant.

Over the years, his “Haganator,” a heavy-duty truss design, became an industry icon. Today, it includes in-truss dust collection, the largest aggregate capacity, and many operator-friendly upgrades.

Vince Hagan invented the mobile batch plant in 1956 • Patented in 1966 – US 3,251,484

Explore Containerized Batching Plants

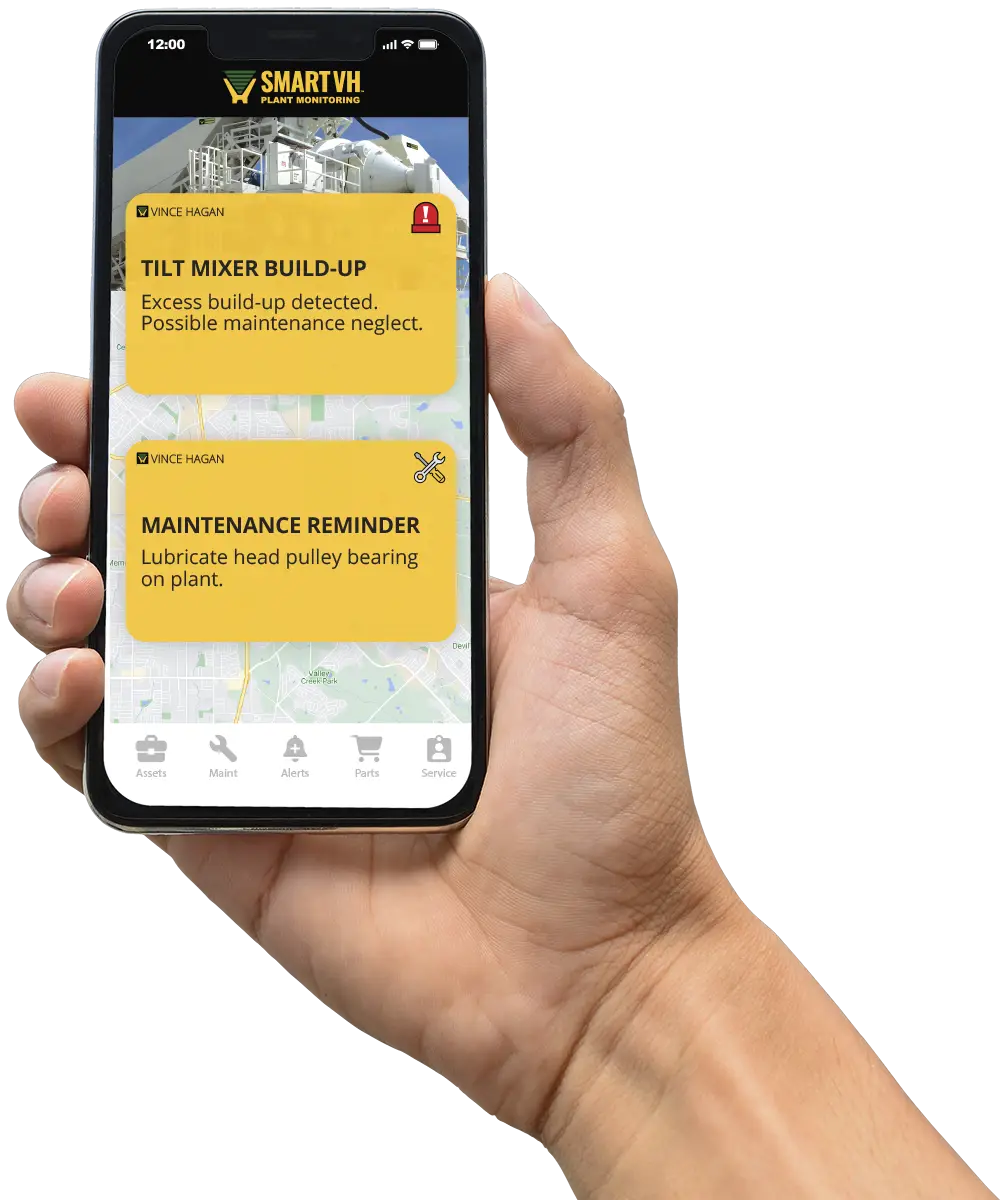

SmartVH™ Plant Monitoring System Reduce Plant Downtime & Maintenance Problems

As industry leading innovators, Vince Hagan and Command Alkon introduce new technology to decrease loading times, increase plant efficiency, reduce CO2 production, and provide state-of-the-art monitoring tools from your mobile devices.

See Vince Hagan Batch Plants In Action

Vince Hagan recently designed, manufactured, and installed an LP Series Stationary Batch Plant, free standing dust collector, and conveyor in South Texas.

Vince Hagan recently designed, manufactured, and installed an HT Mobile Batch Plant and HCA Silo in New York.

Vince Hagan recently designed, manufactured, and installed an LP Series Stationary Batch Plant, free standing dust collector, and conveyor in New Mexico.

Vince Hagan recently designed, manufactured, and installed an LP Series Stationary Batch Plant, free standing dust collector, and conveyor in North Texas.

Vince Hagan recently designed, manufactured, and installed an HT Mobile Batch Plant, HCA Silo, and conveyor in Georgia.

Vince Hagan recently designed, manufactured, and installed an LPM Series Stationary Batch Plant, free standing dust collector, and conveyor in North Texas.

Contact Your Regional Sales Manager

The Vince Hagan Company has been the nation’s leading innovator in concrete batching plants and equipment for over 60 years. Connect with your regional sales manager today to learn more about our equipment and get a customized quote for your project’s needs.

Latin America Sales Manager

Canada Sales Manager

What Makes Up a Concrete Batching Plant

A concrete batching plant is a combination of equipment that brings together water, air, cementitious mixtures, and other aggregate materials to produce concrete for different application types. Depending on production needs and other factors, the producer might choose a mobile concrete batching plant or a stationary concrete batching plant. The batching plant can produce dry batch concrete which is a combination of concrete ingredients and mixed in a truck with water on the way to a project, or wet mix concrete is a combination of concrete ingredients and water into a paving mixer at the site of your batch plant and then discharged into a truck for transport.

A mobile batch plant is designed for maximum portability of the plant to and from different construction sites, doesn’t require concrete foundations, and Vince Hagan offers models that self erect saving you costs on cranes. The patented, heavy-duty steel truss design on our HT Series means the plant can travel as a single load of freight, including dust collection. They stand the tests of time, weather, and high production.

A stationary batch plant can accommodate a wider variety of configurations based on the needs of your project. Our LP series can be transported in two loads, or our LPM and HSM series can be custom designed for higher production capabilities with multiple silos and aggregate conveyors.

Paving mixers, like the Tilt Mixer, Horizontal Shaft Mixer, or Twin Shaft Turbo Mixers enable concrete producers to mix concrete at the site of their batching plant and transport to another job site.

Cement Storage silos are storage units for the ingredients that make up concrete and come in a wide variety of configurations and portability options. The mobile HCA silo is perfect for pairing with the HT Series, self erects, and does not require a concrete foundation. Other silos utilize gravity to distribute the materials onto the conveyors which transport it to the aggregate bins.

Aggregate conveyors is another concrete batch plant add-on that enables more concrete ingredient transport into the production process. Depending on your production needs, Vince Hagan offers a wide variety of mobile and stationary options with wide ranging capacities.

Because concrete production combines finely processed materials, a large amount of dust can be created around the batch plant that many urban and residential areas mandate be controlled. Attached cement dust collector and controllers are implemented on mobile and stationary batch plants to mitigate the dust that is produced and escapes into the surround area.

Depending on the climate or season concrete is being produced in, batch plants might need to incorporate a water chiller or water heater to aid in the very precise production of concrete.

Request a Quote

Since 1956, Vince Hagan has been the standard for batching plants and industry innovation. Fill out the form below to get a quote started with the most trusted name in the industry.