HS Series

Mobile Batch Plant

The HS Series mobile concrete batching plant eliminates the need for aggregate conveyors and can grow as your production needs increase.

Key Specs

Overview

For producers with lower production requirements, typically 40-110 YD³ per hour, Vince Hagan offers a “starter mobile batch plant” version - the HS Series. This plant features a single or dual scale decumulative aggregate batcher, 400 BBL of cementitious storage, 12 yard in-truss cement batcher, and all of the other features of the HT Series plant.

Increase Production Capability as You Grow

Go from 110 to 200 YPH

Increase production by as much as double with the addition of an overhead aggregate bin, optional HCA silo, and bin-feed conveyor.

Features

Hydraulic Self Erect Mobile Plants

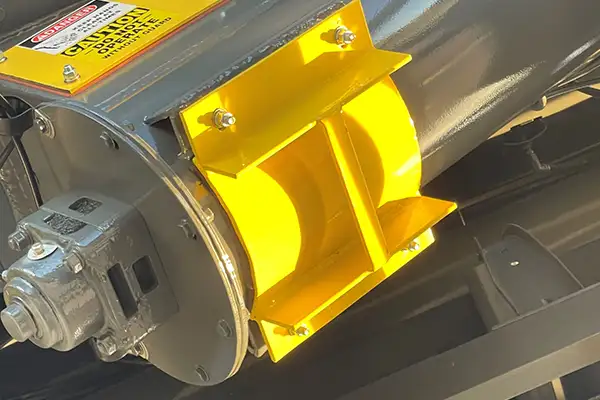

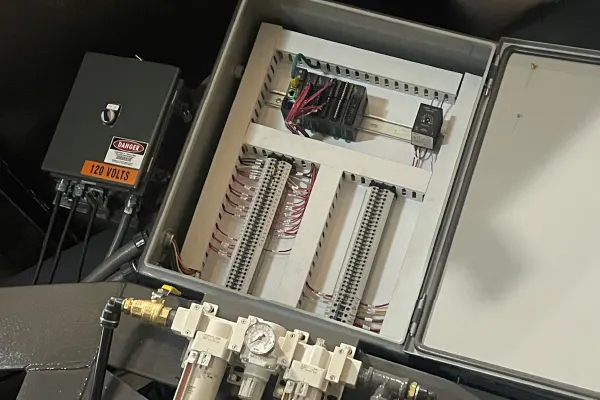

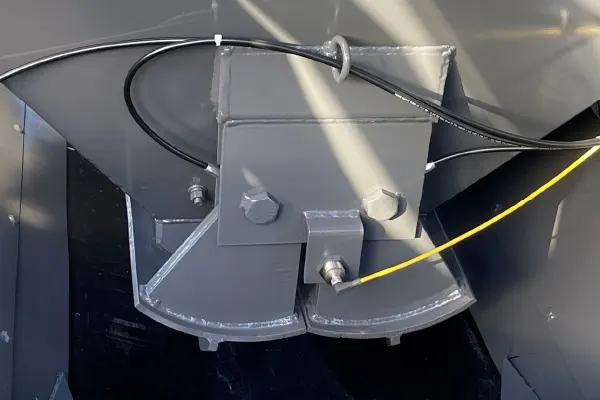

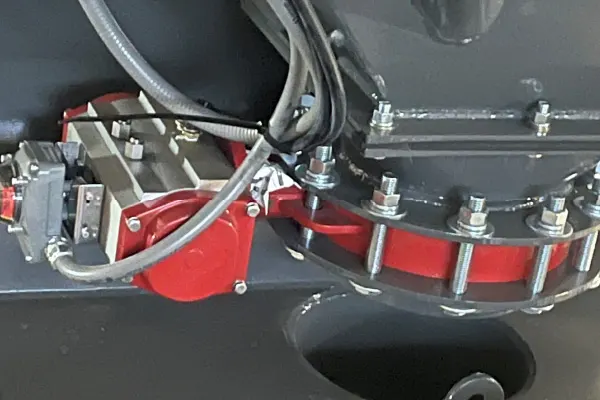

An optional upgrade, the hydraulic self erect package can be added to the mobile plant, auxiliary silo, conveyor, and horizontal shaft mixer. Our original design allows cylinders to retract, protecting them from the caustic environment.

Specifications

| Standard Models | HS Series | HT Series | SHT/CM Series |

|---|---|---|---|

| Capacity (theoretical) | 40-110 Yd³ Per Hour (Transit Mix) | 120-180 Yd³ Per Hour (transit mix) | 180-300 Yd³ Per Hour (Central Mix) |

| Axles (dual tires, 10-hole wheels & air brakes) | Triple | Triple | Four |

| Discharge Height (steel clearance) | 14’-2” | 14’-2” | 14’-10” |

| Overhead Bin, 3 or 4 Compartments (both sides fold down for travel) |

Direct Charge to Batcher | 65 ton/48.1 Yd³ yes |

80 ton/59.2 Yd³ yes |

| Aggregate Batcher Size | 12 Yards - 40,000# | 12 Yards - 40,000# | 12 Yards - 40,000# |

| 4 Point Load Cell 20k Each | Yes | Yes | Yes |

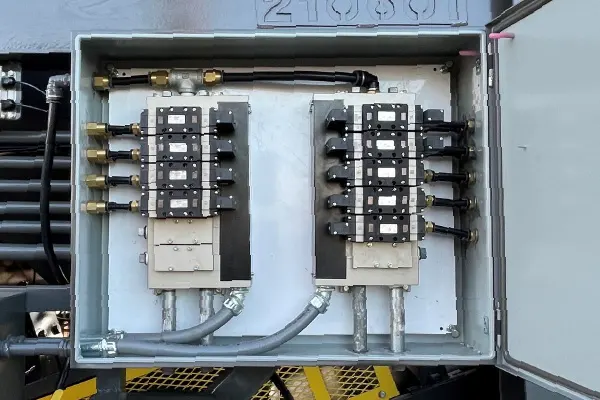

| Aggregate Batcher gates | 2 Double Clam | 2 Double Clam | 2 Double Clam |

| Transfer Belt Conveyor | 36”/30hp 380 fpm |

36”/30hp 380 fpm |

48”/60 hp 650 fpm |

| Deep Troughing Idlers | 35 degrees | 35 degrees | 35 degrees |

| Cement Silo (in-truss design) | 400 bbl/1600 FT³ | 400 bbl/1600 FT³ | 500 bbl/2000 FT³ |

| Cement Feeders, Multi-flight (reversible & independently controlled) |

Twin 12”/25hp/240 cfm yes |

Twin 12”/25hp/240 cfm yes |

Twin 12”/25hp/240 cfm yes |

| Cement Batcher Size | 12 yards - 10,000# | 12 yards - 10,000# | 12 yards - 10,000# |

| 4 Point Load Cell (3k Each) | Yes | Yes | Yes |

| Cement Batcher Discharge | 10” butterfly | 10” butterfly | 10” butterfly |

| Water Meter (piping to discharge) | 3” turbo | 3” turbo | 3” turbo |

| Air Compressor | 15 hp | 15 hp | 20 hp |

| Electrical Service (pre-wired in emt conduit) | 460v/3ph/60hz | 460v/3ph/60hz | 460v/3ph/60hz |

| Travel Dimensions: Length (king pin to rear) Width Height Weight |

61’-0” 12’-0” 14’-6” 52,000# |

61’-0” 12’-0” 14’-6” 64,000# |

65’-6” 12’-0” 14’-6” 87,000# |

Gallery

Plants in Action

Vince Hagan recently designed, manufactured, and installed an HS Mobile Batch Plant in Georgia.

Vince Hagan recently designed, manufactured, and setup an HS Series batch plant to work on one of the largest infrastructure project in Mexico.

Vince Hagan recently designed, manufactured, and installed an HS Mobile Batch Plant in California.

We recently manufactured and installed this direct-charge HS Series Dry Mobile Batch Plant in the Midwest.

Vince Hagan recently custom manufactured and installed an HS Dry Mobile Concrete Batching Plant in North Texas.

Request a Quote

Since 1956, Vince Hagan has been the standard for batching plants and industry innovation. Fill out the form below to get a quote started with the most trusted name in the industry.