HT Series

Mobile Batch Plant

The HT Series is the nation's best selling mobile concrete batching plant that travels as one load in a patented truss design.

Key Specs

Overview

The icon of the Vince Hagan brand, the patented HT Series mobile batch plant sets the industry standard. No other plant design is as time-efficient and cost-effective as the HT Series. The heavy-duty steel truss design includes a host of options such as in-truss dust collector, weighed water system, safety walkways, and more. This means that everything you need travels as one load, saving you time and costs on transport. Our customers have had their plant erect and operational in 8 hours.

The flexibility of our HT Series mobile plants is unparalleled. It’s the only portable batch plant on the market that accommodates most paving mixers, incorporates up to 1400BBL cementitious storage (with dual, optional HCA silos), and is easily maintained with notifications via the SmartVH™ app and non-proprietary parts. Buy a mobile batch plant from the company that invented it!

U.S. Government Patent #3,251,484

High-Performance Series

180-200 YD³ Per Hour

As the top of the line in the series, the HT High-Performance Series combines speed, storage, versatility, and technology into a machine capable of meeting the demands of any ready mix job. For producers looking to maximize production with total mobility and layout flexibility, the HT High-Performance is for you.

This series standard features include up to 80 ton - 4 compartment aggregate bin, up to 1200 BBL cementitious storage (with dual, optional HCA silos), 12” screw feeders, powerful air compressor, and 36” conveyor belt. For greater production speed, this series includes the new Turbo-Flo Armor™ liners in the aggregate batcher and 2’ risers for optimal truck loading speed. With the combination of these components, the HT High-Performance Series is capable of meeting any output demands for high-quality concrete.

Key Specs

Performance Series

120-200 YD³ Per Hour

Stepping up to the HT Performance Series, producers recognize this mobile plant as the industry standard in ready mix concrete production. With an up to 80-ton aggregate bin, optional weighed water system, powerful air compressor, and 36” conveyor belt, the HT Performance Series is perfect for a wide range of producers needing to meet the demands of the market.

For producers in a hurry, the HT Performance Series has an optional retractable self erect system available. The cylinders retract into themselves, protecting them from the caustic environment. The self erect system eliminates the need for costly and time-consuming cranes. Customers have had their plant erected and operational in 8 hours.

Key Specs

Essential Series

120-150 YD³ Per Hour

The HT Essential Series mobile batch plant is designed to maximize production and minimize initial costs. Whether just starting out in concrete production or looking to grow market share, the HT Essential Series is stacked with features any producer needs to deliver high-quality concrete.

It comes equipped with an in-truss, PLC-based dust control system, a 65-ton aggregate bin, 400 BBL in-truss cementitious storage, and much more. With no foundations needed and universal configuration of additional storage silos and aggregate conveyors, the versatility and value of the HT Essential Series is unmatched in the industry.

Key Specs

Features

Add-Ons

Hydraulic Self Erect Mobile Plants

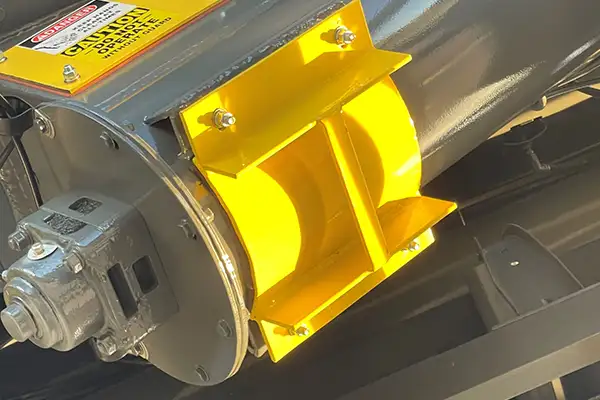

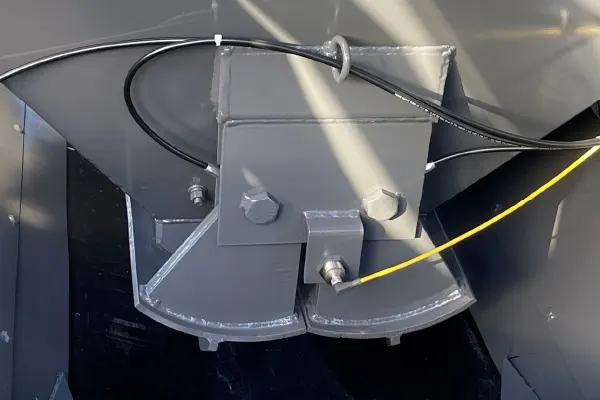

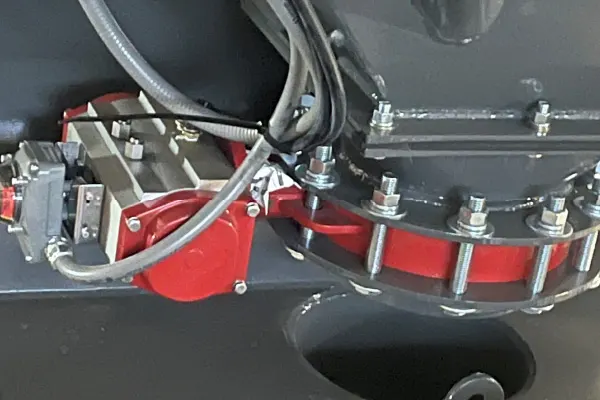

An optional upgrade, the hydraulic self erect package can be added to the mobile plant, auxiliary silo, conveyor, and horizontal shaft mixer. Our original design allows cylinders to retract, protecting them from the caustic environment.

Mobile Wet Batch Production

Our mobile tilt mixers are designed for a true 12-yard batch without spillage. We build mixers to last, with heavy-duty components, the largest bull ring gear in the industry, and an open design to ensure access to all moving parts for ease of maintenance.

No Need to Dig Out with 12′ 9″ Truck Clearance

No other plant and mixer combination gives you a quicker setup and dismantle time, the ability to have the fewest loads of freight, or the consistent quality produced with the compulsory mixing action of this mixer.

Twin Shaft Mixers

Our line of mobile plants pair with a variety of twin shaft mixer sizes.

HT Series Paired with Horizontal Shaft Mixer

HT Series Paired with Twin Shaft Mixer

HT Series Paired with 12 yd³ Mobile Tilt Mixer

Specifications

| Standard Models | HS Series | HT Series | SHT/CM Series |

|---|---|---|---|

| Capacity (theoretical) | 40-110 Yd³ Per Hour (Transit Mix) | 120-180 Yd³ Per Hour (transit mix) | 180-300 Yd³ Per Hour (Central Mix) |

| Axles (dual tires, 10-hole wheels & air brakes) | Triple | Triple | Four |

| Discharge Height (steel clearance) | 14’-2” | 14’-2” | 14’-10” |

| Overhead Bin, 3 or 4 Compartments (both sides fold down for travel) |

Direct Charge to Batcher | 65 ton/48.1 Yd³ yes |

80 ton/59.2 Yd³ yes |

| Aggregate Batcher Size | 12 Yards - 40,000# | 12 Yards - 40,000# | 12 Yards - 40,000# |

| 4 Point Load Cell 20k Each | Yes | Yes | Yes |

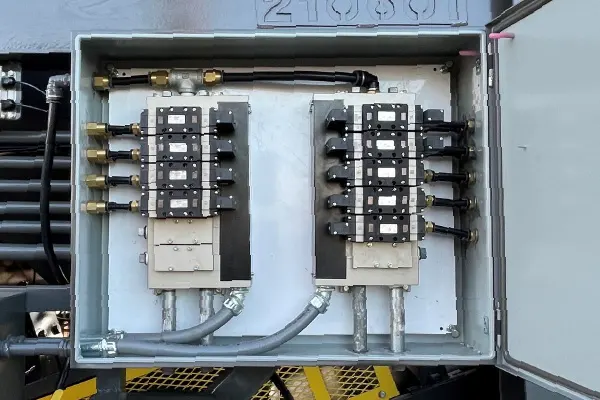

| Aggregate Batcher gates | 2 Double Clam | 2 Double Clam | 2 Double Clam |

| Transfer Belt Conveyor | 36”/30hp 380 fpm |

36”/30hp 380 fpm |

48”/60 hp 650 fpm |

| Deep Troughing Idlers | 35 degrees | 35 degrees | 35 degrees |

| Cement Silo (in-truss design) | 400 bbl/1600 FT³ | 400 bbl/1600 FT³ | 500 bbl/2000 FT³ |

| Cement Feeders, Multi-flight (reversible & independently controlled) |

Twin 12”/25hp/240 cfm yes |

Twin 12”/25hp/240 cfm yes |

Twin 12”/25hp/240 cfm yes |

| Cement Batcher Size | 12 yards - 10,000# | 12 yards - 10,000# | 12 yards - 10,000# |

| 4 Point Load Cell (3k Each) | Yes | Yes | Yes |

| Cement Batcher Discharge | 10” butterfly | 10” butterfly | 10” butterfly |

| Water Meter (piping to discharge) | 3” turbo | 3” turbo | 3” turbo |

| Air Compressor | 15 hp | 15 hp | 20 hp |

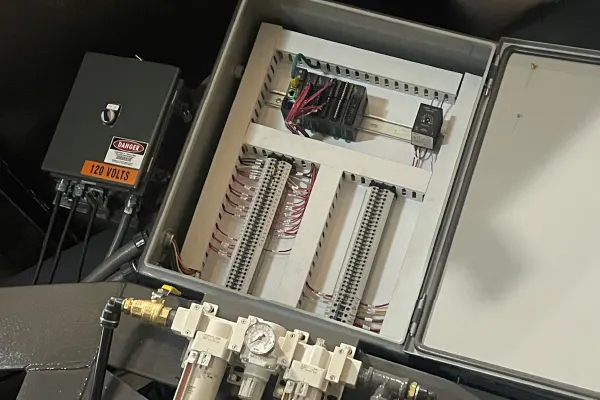

| Electrical Service (pre-wired in emt conduit) | 460v/3ph/60hz | 460v/3ph/60hz | 460v/3ph/60hz |

| Travel Dimensions: Length (king pin to rear) Width Height Weight |

61’-0” 12’-0” 14’-6” 52,000# |

61’-0” 12’-0” 14’-6” 64,000# |

65’-6” 12’-0” 14’-6” 87,000# |

HT Series Gallery

portable Plants in Action

Vince Hagan recently designed, manufactured, and installed an HT Mobile Batch Plant and HCA Silo in New York.

Vince Hagan recently designed, manufactured, and installed an HT Mobile Batch Plant, HCA Silo, and conveyor in Georgia.

Vince Hagan recently designed, manufactured, and installed an HT Mobile Batch Plant, HCA Silo, and conveyor in Ontario.

Vince Hagan recently designed, manufactured, and installed an HT Mobile Batch Plant, HCA Silo, and conveyor in Alberta.

Vince Hagan recently designed, manufactured, and installed an HT Mobile Batch Plant, HCA Silo, and conveyor in Tennessee.

Vince Hagan recently designed, manufactured, and installed an HT Mobile Batch Plant, HCA Silo, and conveyor in Utah.

Request a Quote

Since 1956, Vince Hagan has been the standard for batching plants and industry innovation. Fill out the form below to get a quote started with the most trusted name in the industry.