Mobile Stacking Conveyors

Aggregate Conveyors

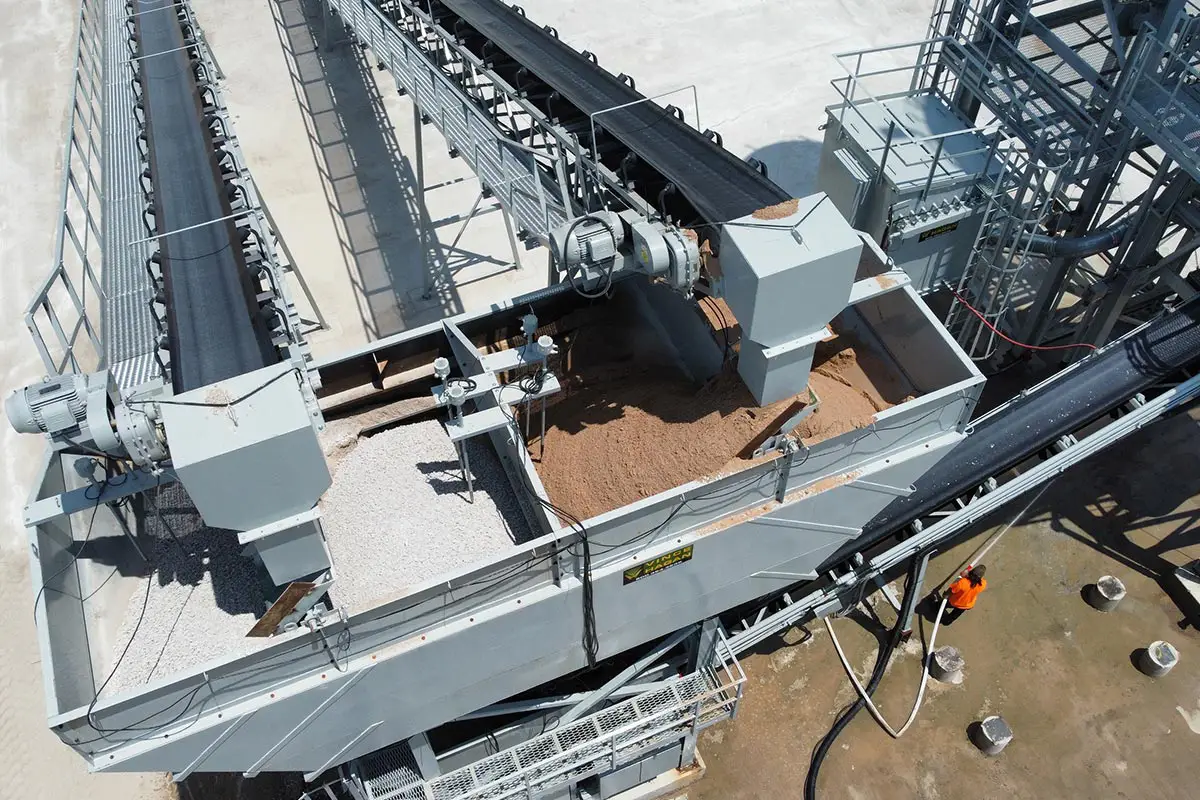

Vince Hagan offers a heavy-duty line of material handling conveyors known for durability.

Key Specs

Overview

Vince Hagan offers a heavy-duty line of material handling conveyors known for durability. Tailor the conveyors to match your plant’s maximum production capacity. We build each conveyor with a heavy-duty 36” deep truss frame that accommodates a 24”-36” wide belt.

Radial stacking conveyors offer flexibility in production capacity and site layout. Utilize a single conveyor to charge multiple bin compartments, or combine conveyors to charge multiple materials at once. Mobile options are available for mobile plant setups.

Radial Stacking Conveyor

Wheels remain fixed for radiating

Standard Components

Standard Equipment

Radial Stacker Options

Gallery

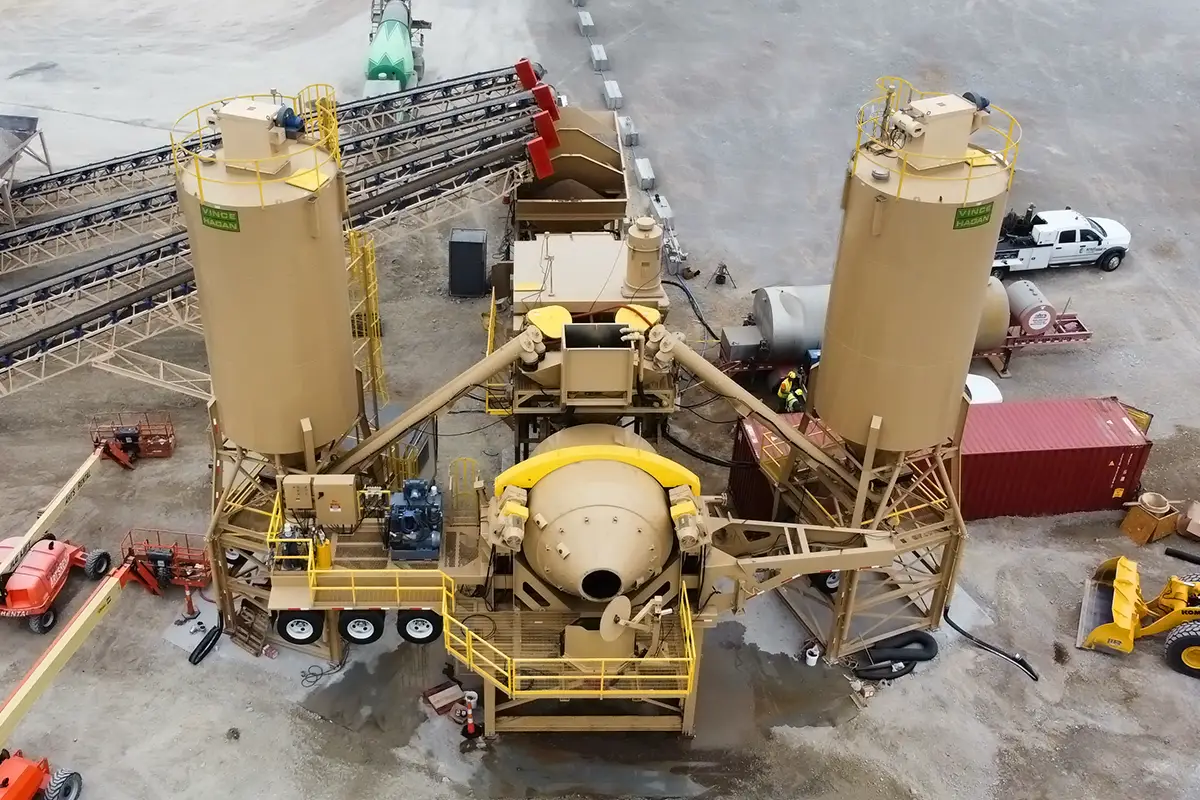

Plants in Action

We recently manufactured an installed this SHT Series, HCA Auxiliary Silo, and Conveyors for a large volume producer in Ohio.

Vince Hagan recently designed, manufactured, and setup an HS Series batch plant to work on one of the largest infrastructure project in Mexico.

Vince Hagan recently designed, manufactured, and installed an HS Mobile Batch Plant in California.

We recently manufactured and installed this direct-charge HS Series Dry Mobile Batch Plant in the Midwest.

We custom engineered and manufactured a new Mobile Central Mix Batch Plant for Ernst Concrete in the Midwest.

Our expert service team is able to assist any producer with plant relocation and new site optimization.

Request a Quote

Since 1956, Vince Hagan has been the standard for batching plants and industry innovation. Fill out the form below to get a quote started with the most trusted name in the industry.