Horizontal Shaft Mixer

HM-10 Series/RCC Mixer

The combination of mixer mobility and high production capabilities.

HM-10 Advantages

Overview

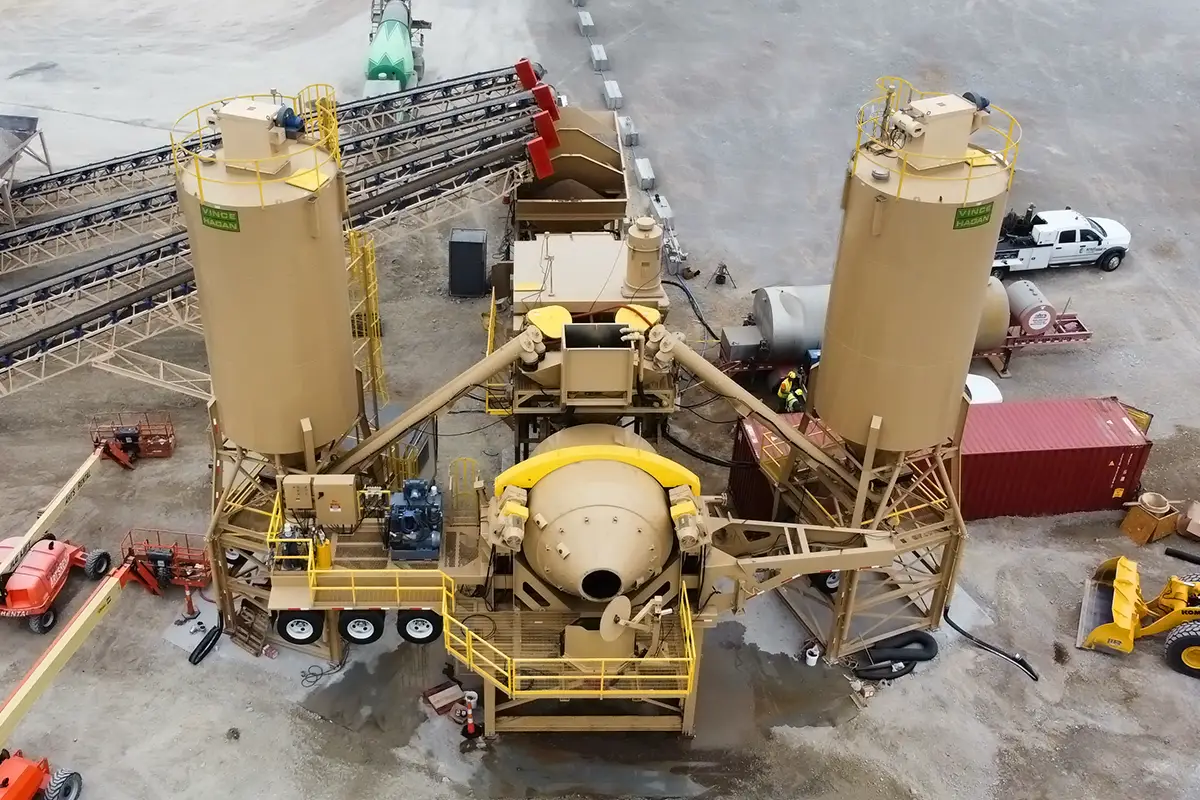

Vince Hagan combined mixer mobility and product consistency when we designed our patented Horizontal Shaft Spiral Blade Mixer. Fully trailerized and self erecting, it moves easily and inexpensively. Plus, you can often forego the need for concrete slabs. These mobility factors mean this mixer can be set up in a day, and on a fast-moving paving job. Additionally, the horizontal mixer does not require chipping out daily like it's tilt mixer counterpart. All of of these features improve your bottom line!

For decades, the largest pavers in the highest concrete production states have chosen the Vince Hagan Horizontal Shaft Mixer for production reliability and mobility.

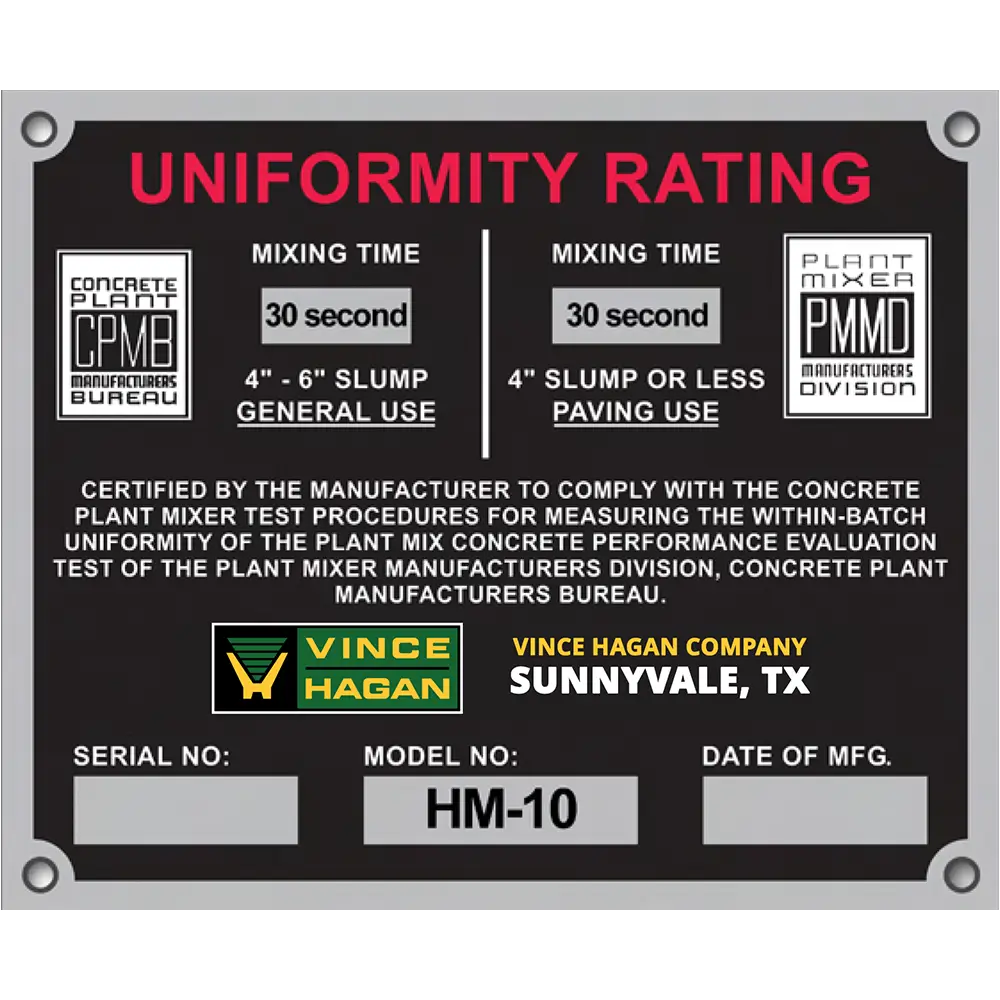

Due to its quick cycle time, the Hagan Mixer produces up to 400 yards per hour with a 30-second mix time. A 20-second mix time has been approved for both 1”–3” slump pacing and 4”–6” slump general use concrete. This mixer is accepted by Army Corps of Engineers, All Military Branches, and Dept. of Transportation.

Adding the RCC upgrade makes this mixer the highest production and most portable RCC mixer on the market. It can mix high and low slump, slurry mixes, cement treated base and roller compacted concrete.

Trailer Features

Key Features

Automatic Grease System

Twin 125 hp motors & oil bath

Self Erect Available

Optional RCC Mixer Upgrade

The Highest Production Portable RCC Mixer on the Market

Gallery

Plants in Action

We recently manufactured an installed this SHT Series, HCA Auxiliary Silo, and Conveyors for a large volume producer in Ohio.

Vince Hagan recently designed, manufactured, and setup an HS Series batch plant to work on one of the largest infrastructure project in Mexico.

Vince Hagan recently designed, manufactured, and installed an HS Mobile Batch Plant in California.

We recently manufactured and installed this direct-charge HS Series Dry Mobile Batch Plant in the Midwest.

We custom engineered and manufactured a new Mobile Central Mix Batch Plant for Ernst Concrete in the Midwest.

Our expert service team is able to assist any producer with plant relocation and new site optimization.

Request a Quote

Since 1956, Vince Hagan has been the standard for batching plants and industry innovation. Fill out the form below to get a quote started with the most trusted name in the industry.