Horizontal Shaft Mixers

Horizontal Shaft Concrete Mixers come in a wide variety of size capacities. Along with normal concrete, they are popular for producing RCC (Roller Compacted Concrete) and SCC (Self Consolidating Concrete). Horizontal mixers have one or two horizontal shafts. For use in construction projects some manufacturers offer their larger mixers mounted on trailers for ease of relocation between job sites.

The Vince Hagan Horizontal Shaft Spiral Blade Concrete Mixer is available in three sizes 4.5, 8.0 and 10.0 cubic yard capacity. This concrete mixer is designed to be portable and used with the HT, Super HT and HTS portable plants. The Vince Hagan Horizontal Shaft Spiral Blade Mixer plant and mixer combination gives you the ability to have the fewest loads of freight, quick setup and dismantle time and the consistent quality produced with the compulsory mixing action. The mixer and plant can be ready for production within two days after arriving on the project.

• Production rate for the 4.5 cu. yard mixer 120 to 150 cu. yards per hour

• Production rate for the 8.0 cu. yard mixer 230 to 260 cu. yards per hour

• Production rate for the 10.0 cu. yard mixer 320 to 400 cu. yards per hour

The horizontal shaft spiral blade mixer was patented by Vince Hagan with U.S. Government Patent # 4,854,711

Types of Horizontal Shaft Concrete Mixers

Single Shaft Concrete Mixers

The first is a single shaft mixer that has a series of blades mounted to a single common shaft that passes through the center of a round mixing drum, an opening in the top to introduce the concrete ingredients, and a door in the bottom to allow the mixed concrete to be discharged. The drawback of this is that the mixer must be mounted high enough for the dump truck or mixer truck to be able to drive underneath it. These can range in mixing capacity from 4.5 cubic yards up to 10 cubic yards. Mix times can be as short as 30 seconds for a 10 yard mixer.

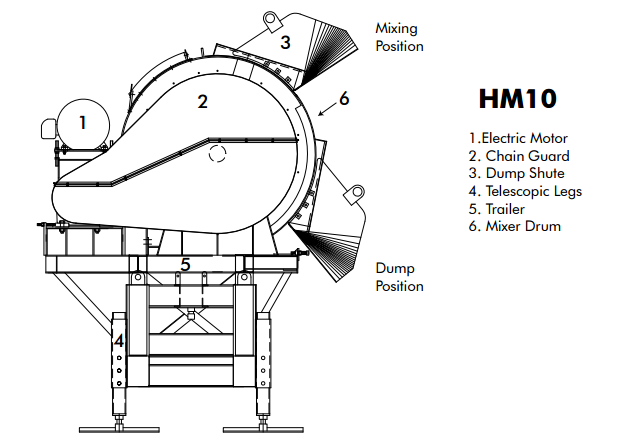

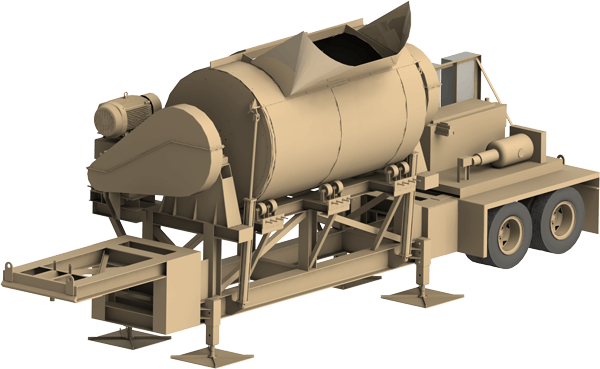

One variation of this is a single shaft horizontal mixer that has a rotation mechanism that turns the drum to discharge the concrete and allows the mixer blades to sweep the concrete out of the mixer. This concept was originally patented by Vince Hagan in 1989 (U.S. Government Patent # 4,854,711). The advantage of this design is that it allows the mixer to sit lower so that a dump truck can pull up beside rather than having to be able to pass completely under it.

Reversing Drum Concrete Mixers

The second type of horizontal mixer is a reversing drum mixer. This is very similar in concept to the drum of a mixer truck. It rotates one direction to mix and the other to discharge the finished concrete.

Twin Shaft Concrete Mixers

The third and final type of horizontal mixer is a twin shaft mixer. They are known for their multiple blades or shoes that are mounted to two parallel shafts that provide a thorough mixing action. These can range in mixing capacity from 2 cubic yards up to 8 cubic yards. These typically utilize a bottom trap door type of discharge. Again this type of mixer must be mounted high enough for the dump truck or mixer truck to be able to drive underneath it. This type of mixer is also popular for use in the precast and pre-stressed concrete industries.